When it comes to silage, the quality of your feed starts long before it reaches the stack. A clean cut, even drying, and contamination-free raking form the foundation of top-quality silage. And when you get these steps right, your forage harvester is set up for maximum efficiency and precision.

CLAAS machines are designed to work together like pieces of a puzzle — each step preparing the crop for the next. Here’s how the DISCO Mower, VOLTO Tedder, and LINER Rake combine to give your silage the best possible start.

Step 1: DISCO Mowers – Clean cut, clean start

The mowing stage sets the potential for everything that follows. With CLAAS MAX CUT technology, DISCO mowers deliver an uncompromisingly even cut. The unique wave-shaped cutterbar ensures maximum overlap between discs, giving you a uniform stubble height and a smooth, clean crop.

Thanks to Active FLOAT suspension, the mower “floats” over the ground, minimising soil contact and reducing contamination. Less ash means cleaner forage and higher feed value – for every 1% reduction in raw ash contamination, you’ll see an increase of 0.1 MJ NEL/kg dry matter!

And with wide working widths and quick blade changes, DISCO makes light work of big paddocks, saving time and fuel while setting the stage for perfect regrowth.

Step 2: VOLTO Tedders – Spread fast, dry evenly

Once cut, forage needs to dry quickly and evenly to preserve nutrients and avoid weather risks. The VOLTO Tedder with MAX SPREAD rotor system is engineered to do exactly that.

With tine arms angled at 29.3°, VOLTO ensures forage is spread uniformly across the full working width. This consistent distribution results in faster, more even drying, reducing clumps and preventing “green spots” that can cause problems later in the stack. Gentle handling also protects the crop structure, helping to maintain feed quality.

The result? A perfectly conditioned crop that dries evenly and flows smoothly through subsequent raking and harvesting.

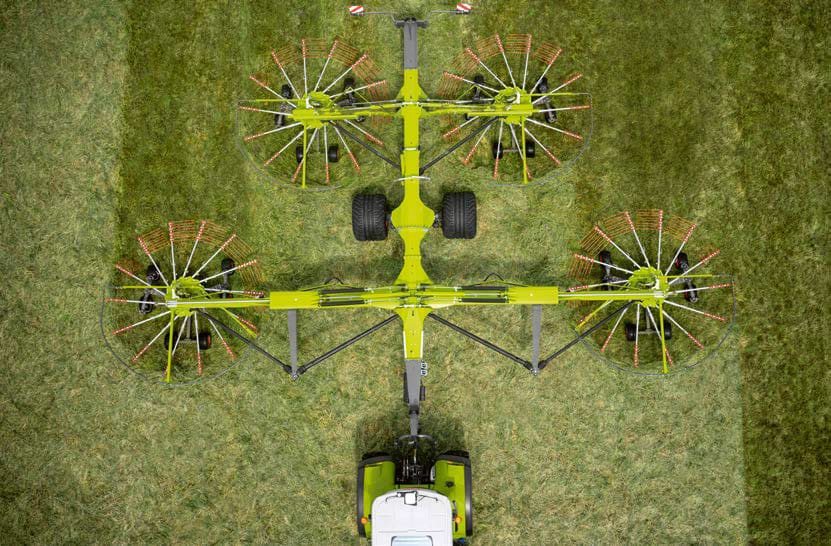

Step 3: LINER Rakes – Form the perfect row

Raking is the last chance to keep contamination low and prepare the crop for your harvester. The LINER rake’s contour-following rotor chassis ensures the tines track the ground closely without scraping in soil. The large chassis tyres mean less pressure on the ground for maximum soil protection, and with the 6-wheel chassis you get 75% more tyre contact area than a 4-wheel.

Thanks to the cardan double-pivot joint, the rotor moves freely in multiple directions, protecting both the crop and the sward, even on uneven terrain. The outcome is consistent, fluffy swaths that feed smoothly and efficiently, without blockages or uneven chop.

All this means cleaner forage with reduced ash content, an essential factor for silage that keeps well and feeds better.

Why It Matters: A better base for your harvester

When the DISCO, VOLTO, and LINER work in sequence, they create the perfect conditions for your JAGUAR forage harvester to shine. The clean cut, even drying, and contamination-free swaths allow it to maintain a steady crop flow, chop uniformly, and deliver silage with the ideal structure for compaction and fermentation.

It’s a system designed to give you better silage, higher feed value, and greater efficiency — right from the start. Because when you kick it off right, you finish strong.

And, with our early order program you can secure the gear you need with the deal that works for you. Ordering now for next season guarantee’s you a build slot in the factory and allows you to select the exact specs you need to suit your operation. Place your order now and be ready to make perfect silage next season.