CLAAS VOLTO Tedders

CLAAS tedders are the ideal partner for farmers who prefer to do their own forage harvesting.

CLAAS VOLTO Tedders

Working large areas in the shortest possible time is what good tedders do. Whether mounted or trailed, CLAAS hay tedders ensure that your crop dries quickly thanks to their working widths and superior technologies. When it comes to maximum performance and spreading width, the CLAAS VOLTO hay tedder stands supreme and is available in 5.2-15.1m working widths. All models feature MAX SPREAD crop flow technology that enables you to work fast and efficiently, saving time and making the job easier.

Specifications for Mounted VOLTO Tedders

| 1100 | 900 | 800 | 700 | 60 | 55 | |

|---|---|---|---|---|---|---|

| Working width (m) | 10.70 | 8.70 | 7.70 | 6.70 | 5.80 | 5.20 |

| Rotors | 10 | 8 | 6 | 6 | 6 | 4 |

| Number of tine arms per rotor | 6 | 6 | 7 | 6 | 5 | 6 |

| Rotor diameter (m) | 1.50 | 1.50 | 1.70 | 1.50 | 1.30 | 1.70 |

Specifications for Trailed VOLTO Tedders

| 1500 | 1300 | 1100 | 900 | 800 | |

|---|---|---|---|---|---|

| Working width (m) | 15.1 | 13.0 | 10.7 | 8.70 | 7.70 |

| Rotors | 14 | 12 | 10 | 8 | 6 |

| Number of tine arms per rotor | 6 | 6 | 6 | 6 | 7 |

| Rotor diameter (m) | 1.50 | 1.50 | 1.50 | 1.50 | 1.70 |

| Rear steering axle | Optional | Optional | Not available | Not available | Not available |

Resources

Compact Class vs. Large Series

The compact class – has working widths of 5.20-5.80m and a low weight, the VOLTO compact class is specially designed for smaller tractors. These machines are the ideal companions for small or medium-sized farms that harvest their own forage.

The large series (with trailed and mounted options) – helps you think big and swath big. From 6.70-15.10m, you’ll get the job done quickly and efficiently. This saves you valuable time and makes your work even more comfortable.

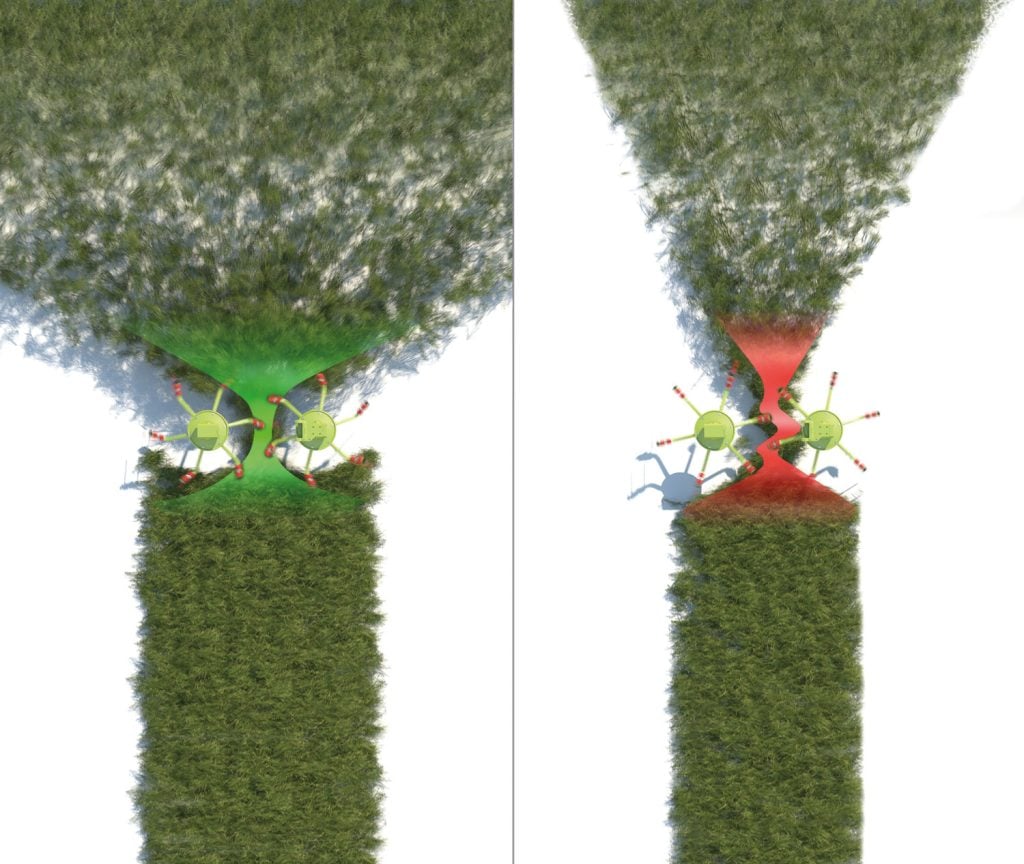

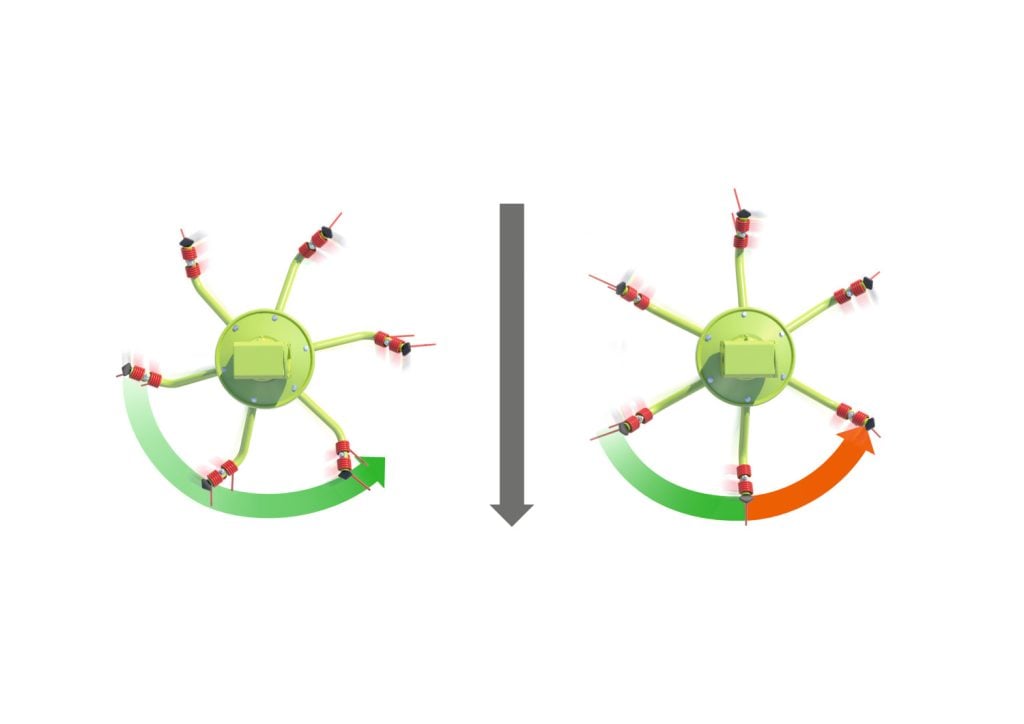

VOLTO MAX SPREAD Concept

Thanks to the trailed tine connection in the MAX SPREAD crop flow concept, the tines are always positioned in or crosswise to the direction of travel as the crop is taken up. In conventional designs, the tines operate opposed to the direction of travel after just half of the pick-up area, thus limiting the forward speed. In the MAX SPREAD crop flow system, the tines operate for 33 percent longer in or crosswise to the direction of travel. So MAX SPREAD enables you to work significantly faster, or with a lower engine speed.

Straight-Line Crop Flow for Gentler Transfer

Since the tines are always positioned at right angles to the crop during pick-up, they can deflect to the rear in the direction of the tine winding. This offers the advantage over conventional systems that the crop flow between the rotors is almost perfectly linear. This creates more space for the crop transfer, and ensures enhanced throughput and exceptionally gentle handling of the forage. The MAX SPREAD concept therefore also allows the tedding of leafy crop types such as lucerne at reduced engine speeds.

More Uniform Distribution

The 29.3° trailed connection also has a positive impact on crop delivery. In the same way as the trailed spreading blades of a fertilizer spreader, this configuration ensures a wider and more even distribution of the harvested crop, for an optimal spread pattern. This fertilizer spreader effect is further supported by tine tension release in the direction of the winding, to spread the crop over the entire width.

CLAAS VOLTO Tedders

Interested?

Drop us your details, and we’ll get in touch with more information.

Similar Machines

CLAAS DISCO Rear Mowers

CLAAS LINER Dual-Rotor Side Swather

CLAAS QUADRANT 5300 EVOLUTION Baler

Find a Dealer

Find your nearest CLAAS Harvest Centre dealer. We’re here to help you get what you need, close to home.