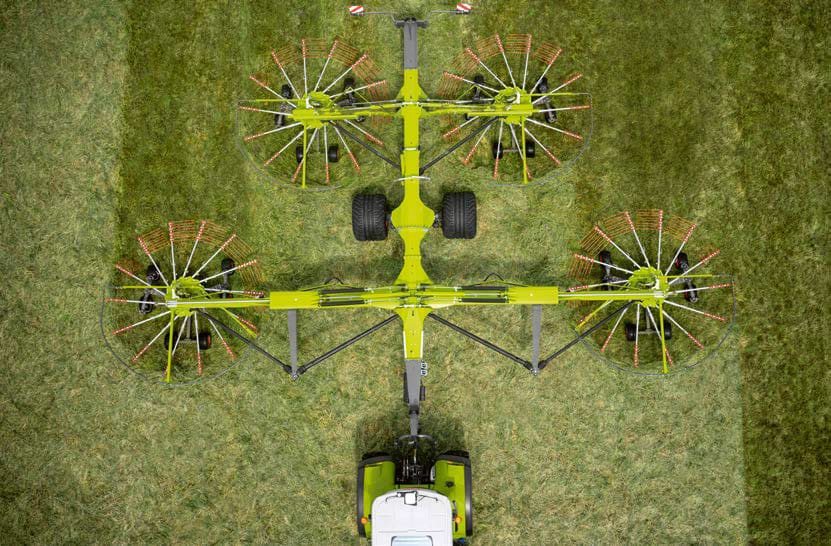

CLAAS LINER Four-Rotor Swather

Ground-contour following. Raking performance. Forage quality.

CLAAS LINER Four-Rotor Swather

Because forage quality is our number one priority too and we know that your time is limited, we take care to protect your resources. We make sure that your grass sward remains intact, your field is quickly cleared, and your livestock are healthy and productive. How do we manage that? Through intelligent engineering and perfectly coordinated machine components, customised to suit your needs.

CLAAS Four Rotor Swather

Continuously lubricated rotor drive assembly

The swathing transmission is located in a rugged cast housing (rotor drive assembly) which is filled with oil and hermetically sealed. So the core component is maintenance-free.

The CLAAS spheroidal graphite iron cam track

High performance under all conditions – its spheroidal graphite iron construction gives the cam track the strength required to withstand any load.

PROFIX tine arm attachment system

In the event of a collision, the tine arms deflect at a predefined bending point to provide optimum protection for the rotor drive assembly.

JET effect

During lifting, the front section of the rotor is raised first and during lowering, the rear chassis wheels touch down before the front wheels

A tidy job

CLAAS has been using the double-angled silage tine for over 20 years. The specially shaped 9.50 mm thick tines are bent at an angle of 10° at the end to ensure a clean pick-up.

TREND vs BUSINESS

The LINER 4700 / 4800 TREND – if you opt for this machine, you benefit from simple, direct operation via spool valves. Furthermore, the LINER 4700 / 4800 TREND needs only two double-acting spool valves for the front arms and the mainframe and telescopic arm. A single-acting spool valve is additionally required to control the rear rotors. With sequential control, this spool valve is not needed. Alternatively, you can choose the PLUS control option and take advantage of the individual lift function for the front rotors and more convenient folding via the CEMIS 10 terminal.

TREND machines are designed to allow the operator to have simple rake operation using the tractors technology and headland management systems.

The LINER BUSINESS – includes direct operation via the CEMIS 700 or the tractor’s ISOBUS screen and includes numerous automatic functions designed to lighten the operator’s load. A wide variety of machine parameters can be individually configured, saved and adapted to the field conditions with just one click. Optional LED lighting can also be added and includes a total of six work lights for optimal visibility even at night

Specifications

| 4900 BUSINESS PRO | 4800 BUSINESS | 4800 BUSINESS PRO | 4800 TREND | 4700 BUSINESS | 4700 TREND | |

|---|---|---|---|---|---|---|

| Working width (m) | 10.10-15.00 | 9.30-13.60 | 9.30-13.60 | 9.30-13.60 | 9.30-12.70 | 9.30-12.70 |

| Swathing rotor | 4 | 4 | 4 | 4 | 4 | 4 |

| Swathing rotor diameter (mm) | 3,800 | 3,500 | 3,500 | 3,500 | 3,300 | 3,300 |

| Tine bars per swathing rotor | 14 | 12 | 12 | 12 | 12 | 12 |

| PROFIX tine arm attachment system | Yes | Yes | Yes | Yes | Yes | Yes |

CLAAS LINER

Interested?

Drop us your details, and we’ll get in touch with more information.

Finance Calculator

Use our handy tool to estimate repayments.

Loan Amount

Loan Length / Period

Interest rate

Disclaimer: This calculator tool is provided for estimation purposes and should not be taken as an official loan application or offer of a loan. Actual repayment amounts can depend on different factors and repayment frequency options may not always be available. We recommend you contact our finance team to learn more about available rates and options based on your circumstances.

Similar Machines

CLAAS LINER Dual-Rotor Side Swather

CLAAS LINER Dual-Rotor Central Swather

CLAAS DISCO Rear Mowers

CLAAS QUADRANT 5300 EVOLUTION Baler

Find a Dealer

Find your nearest CLAAS Harvest Centre dealer. We’re here to help you get what you need, close to home.