CLAAS LEXION 8000-7000 Combine Harvester

What makes our CLAAS Combine Harvesters so special, is much more than the Harvester itself, it’s about the service, the know-how, the technology and above all, it’s about what enables you to harvest successfully. So you are literally investing in more than just a machine. Since 1995, CLAAS have been pushing the boundaries with LEXION innovation and we’re excited to celebrate the milestone with CLAAS producing 500,000 combines worldwide, this year.

We have AUSPRO models which are specifically kitted out with additional specifications tailored for the Australasian market. Designed to handle the unique demands of conditions down under, AUSPRO delivers enhanced performance and reliability, ensuring your LEXION is ready for anything your farm throws at it. Request to find out more here.

CLAAS LEXION 8000-7000

NEW Cab

Increased volume, comfort & ergonomics – including a new high-resolution 12″ CEBIS touchscreen display provides intelligent operator assistance to improve efficiency.

NEW engine

16.2 L MAN D42 engine for LEXION 8800 TERRA TRAC now boasts 700 hp

NEW grain tank

18,000 litre grain tank, discharge rate up to 180 l/s.

Wheeled or TERRA TRAC

CLAAS TERRA TRAC, more driving comfort and suited to 3m CTF.

NEW spout

Cutterbar widths up to 15.30m optimise the crop flow

Specifications

| 8600 | 8700 | 8800 | |

|---|---|---|---|

| Engine | MAN D38 | MAN D38 | MAN D42 |

| Maximum output (ECE R 120) (kW/hp) | 440/598 | 475/646 | 515/700 |

| Engine cylinders/displacement (No./L) | 6/15.6 | 6/15.6 | 6/16.2 |

| Threshing drum width (mm) | 1700 | 1700 | 1700 |

| Main concave area (m2) | 1.55 | 1.55 | 1.55 |

| Rotor concaves (Quantity) | 6 | 6 | 6 |

| Grain tank (L) | 15000/18000 | 15000/18000 | 15000/18000 |

| Total sieve area (m2) | 6.2 | 6.2 | 6.2 |

| Fuel tank capacity (L) | 1150 | 1150 | 1150 |

| Unloading rate (L/s) | 180 | 180 | 180 |

Specifications Continued

| 7600 | 7700 | |

|---|---|---|

| Engine | MAN D26 | MAN D26 |

| Maximum output (ECE R 120) (kW/hp) | 373/507 | 404/549 |

| Engine cylinders/displacement (No./L) | 6/12.4 | 6/12.4 |

| Threshing drum width (mm) | 1420 | 1420 |

| Main concave area (m;sup2;) | 1.30 | 1.30 |

| Rotor concaves (Quantity) | 5 | 5 |

| Grain tank (L) | 12500 | 13500 |

| Total sieve area (m2) | 5.1 | 5.1 |

| Fuel tank capacity (L) | 1150 | 1150 |

| Unloading rate (L/s) | 130/180 | 180 |

Combine Attachment Options

VARIO Cutterbars – the new generation of VARIO cutterbars are the first choice for harvesting grain or rapeseed. They are ideally suited to deliver high performance and high area output, whether operating in low or high yield output. The ability to adjust the VARIO cutterbar table ensures an optimal crop flow at all times and an increase in total machine performance of up to 10%.

CONVIO Draper Cutterbars – Draper cutterbars are used for low-growing and low-fruiting stalk crops or difficult conditions which may necessitate very low cutting. The flexible cutterbar table ensures optimal ground contour following, even with large widths, while the belts make for a gentle and even crop flow.

Celebrating over 500,000 CLAAS Combines

CLAAS celebrated half a million combine harvesters built since 1936 earlier this year – 500,000 CLAAS combine harvesters are, above all, 500,000 success stories, because farmers and contractors worldwide have placed their trust in us 500,000 times,” explains Jan-Hendrik Mohr, CLAAS CEO. “We are therefore celebrating this anniversary internationally with a global roll-out of several anniversary machines to reflect on and appreciate our international competence and production network for combine harvesters”.

Have you seen the special edition LEXION in AUS?

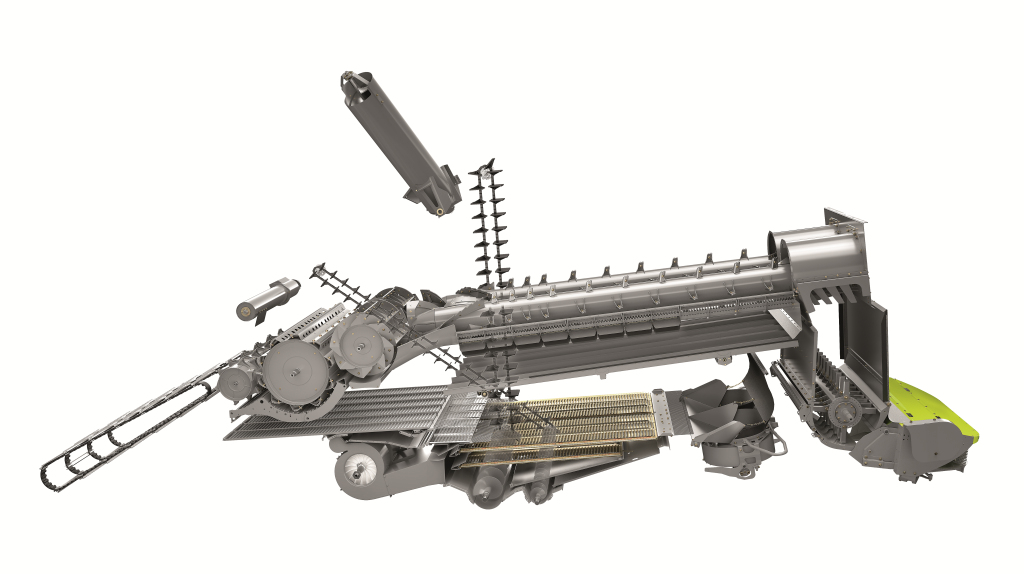

APS SYNFLOW

- The 450 mm accelerator drum in the APS SYNFLOW HYBRID starts an extremely efficient threshing process that allows you to achieve outstanding throughput rates. It accelerates the crop flow smoothly to as much as 20 m/s. In so doing, it generates a high centrifugal force which enables maximum separation performance across all concave areas.

- Large drum diameters and small contact angles enable particularly flat transitions between the threshing and feeder drums, as well as the rotors. This means that there is a straight, fuel-saving crop flow through the combine harvester. What’s more, there are no unnecessary changes in speed or direction of flow. This makes for gentle straw handling and fuel savings.

CEMOS

- Supported by the artificial intelligence of CEMOS AUTOMATIC, the LEXION autonomously determines the best setting for the field, continually adjusts the threshing, cleaning and separation settings for maximum throughput, grain quality, and fuel efficiency. Field testing has shown the CEMOS AUTOMATIC system to improve LEXION’s performance by 10%.

- The FIELD SCANNER sensor detects the height of the plants while the material feed height sensor in the feeder housing evaluates the crop flow. On the basis of these data, CEMOS AUTO HEADER actively controls the position of the reel and the VARIO cutterbar table. This results in an optimal crop feed at all times along with a significant reduction in the workload for the operator.

DYNAMIC POWER

- DYNAMIC POWER automatically adjusts the engine output of your LEXION to the operating conditions. This means that you are always running with the most efficient power curve when operating under partial load and can save – during swathing, for example – up to 10% of fuel. At full load when the grain tank is being unloaded and the straw chopper is engaged, for example, maximum engine output is automatically maintained.

- DYNAMIC COOLING adjusts its speed automatically and, above all, in accordance with the degree of cooling required. Regardless of outside temperature, DYNAMIC COOLING is able to cope easily. The system not only delivers reliable cooling but also uses a curtain-effect air flow to reduce the extent to which dust is able to rise. DYNAMIC COOLING requires 20 kW less engine output, thereby helping you to save fuel.

A Closer Look at the CLAAS LEXION

AUSPRO Demo Tour 2025/2026

Experience the performance of the CLAAS LEXION on your farm by registering for a live demo. Witness the efficiency of the LEXION’s APS SYNFLOW HYBRID threshing system, minimal grain loss, comfort and ability to handle the toughest conditions firsthand.

This is your opportunity to see the results for yourself – so register by completing an enquiry form today.

Interested?

Drop us your details, and we’ll get in touch with more information.

Find a Dealer

Find your nearest CLAAS Harvest Centre dealer. We’re here to help you get what you need, close to home.