Five machines. One system. Perfect silage.

When it comes to making top-quality silage, every stage matters — from the first cut to the final roll on the stack. At every step of the process, minimising contamination is key to maximising the quality of your silage and production from your heard. For every 1% reduction in raw ash contamination, you’ll see an increase of 0.1 MJ NEL/kg dry matter!

CLAAS brings together five specialised machines, each designed to perform a critical role in the silage-making process. Together, they are Perfect Silage Partners, a complete system that delivers cleaner cuts, faster drying, smoother crop flow, and tighter compaction.

Because when every piece works perfectly, your silage does too.

Plus, take advantage of our early order program and secure great benefits – locked-in pricing, guaranteed delivery, exclusive warranty options, and bonus JAGUAR specs worth up to $75,000.

Step 1: DISCO Mowers – Clean Cut, Clean Start

The quality of your silage begins the moment the mower hits the field. CLAAS DISCO mowers set the foundation with the MAX CUT cutterbar, delivering an even, precise cut that ensures uniform stubble height and crop presentation. The secret lies in the wave-shaped mower bed and Active FLOAT suspension, allowing the mower to “float” over the ground and reduce soil contamination. Less ash means cleaner forage and higher feed value — and with wide working widths and quick-change blades, DISCO helps you cover more ground efficiently.

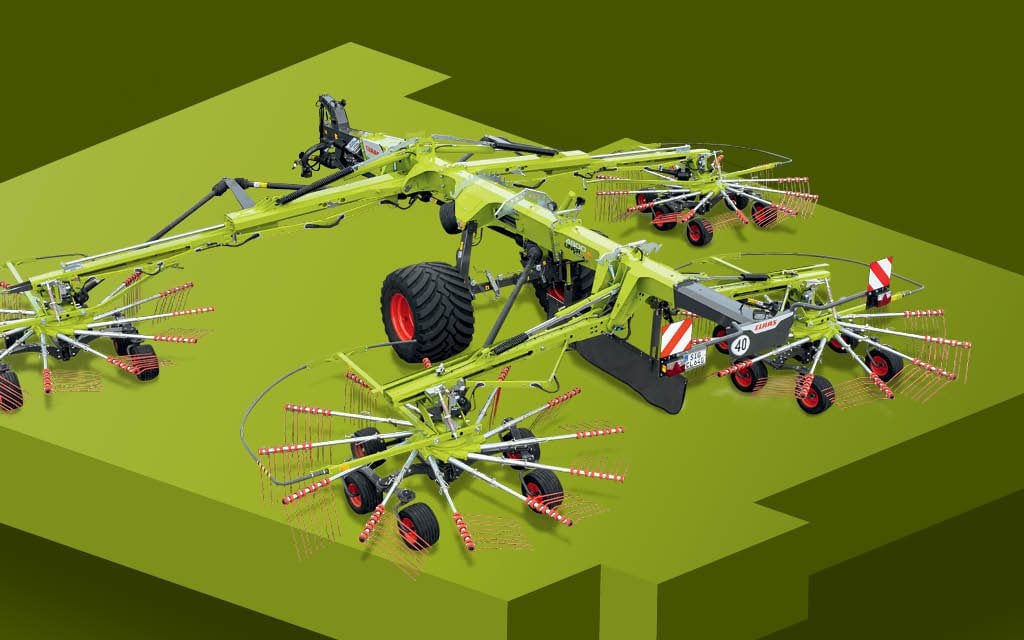

Step 2: VOLTO Tedders – Spread Fast, Dry Evenly.

Once the crop is cut, even drying is key to preserving feed quality and avoiding weather risk. The VOLTO Tedder with MAX SPREAD rotor technology uses tine arms angled precisely at 29.3° to deliver a uniform spread pattern. This ensures faster, more consistent drying. No clumps, no “green spots,” just an evenly conditioned crop ready for raking and harvest. Gentle handling preserves leaf integrity and nutritional value, setting up the next machine in the chain for success.

Step 3: LINER Rakes – Form the Perfect Row

Raking is the last step before harvest and it’s your final opportunity to protect silage quality. The LINER rake uses a contour-following rotor chassis that hugs the ground, avoiding soil pickup and keeping contamination to a minimum. Its cardan double-pivot joint allows free movement in all directions, ensuring clean swaths even on uneven paddocks. The result? Perfectly shaped, consistent windrows that feed smoothly into the JAGUAR harvester, eliminating blockages and uneven chop.

Kicking It Off Right: the perfect start for high-quality silage

When it comes to silage, the quality of your feed starts long before it reaches the stack. A clean cut, even drying, and contamination-free raking form the foundation of top-quality silage. And when you get these steps right, your forage harvester is set up for maximum efficiency and precision.

Step 4: JAGUAR Forage Harvester – Chop with Precision, Every Load

At the heart of the system, the JAGUAR turns preparation into performance. With the V-FLEX chopping cylinder, knives are arranged in a V pattern for smoother, more even cutting forces and consistent particle length. The PREMIUM LINE components and CEMOS AUTO KNIFE sharpening system ensure the chop stays precise all day long. Meanwhile, the NUTRIMETER sensor measures dry matter and crop composition in real time, automatically adjusting length-of-cut and additive dosing to produce silage that compacts evenly and ferments predictably.

Step 5: TORION Wheel Loader – Finish Strong at the Stack

The final step is where all that precision pays off. With its balanced design, powerful drivetrain, and high torque, the TORION delivers the muscle and control needed to manage the stack efficiently. Faster, more even distribution of forage gives you more time for compaction, meaning higher density, fewer air pockets, and better fermentation. The VARIPOWER transmission ensures smooth, continuous speed control for precise loading and pushing, while exceptional visibility keeps operators confident and safe on the ramp.

Every machine in the CLAAS silage range plays a critical part in the puzzle. Together, they create a seamless chain — from clean cutting and fast drying, to smooth raking, precise chopping, and perfect compaction.

This is what Perfect Silage Partners is all about:

Five machines. One system. Perfect silage.

Explore the Full System

CLAAS DISCO Large-Scale Mowers

CLAAS VOLTO Tedders

CLAAS LINER Four-Rotor Swather

CLAAS TORION 1611P-1913 Wheel Loader

Book a demo today

Keen to book a demo or just chat? Leave your details below and one of our team will be in touch soon.

CLAAS Greenline Terms and Conditions:

*Standard CLAAS Financial Services lending criteria, terms, conditions and fees apply. Establishment fee $295. 0.99% p.a on CLAAS Greenline equipment requires a minimum 30% deposit, followed by monthly repayments over 12 months. GST back in month 3. Offer includes DISCO Mowers, VOLTO Tedders and LINER Swathers. Offer excludes balers. Offer valid on equipment quoted and approved by 30/03/2026 and settled by 01/10/2026 or while stocks last. If finance base rates move by more than 0.25%, CLAAS Financial Services reserve the right to re-quote. Images illustrative only.

CLAAS JAGUAR GREEN-EYE Package Terms and Conditions:

^Strictly limited to new 900 SERIES and 800 SERIES machine orders placed with CLAAS prior to 30/03/26. Any orders placed after 30/03/26 will NOT be eligible for the full specification discount. GREEN-EYE offer is strictly limited to the package options and cannot be granted unless the full specification offer is taken, which includes a version of V-FLEX and variable header drive on all JAGUAR 900 series machine.